|

||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Milestones |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dawn of Meiwa Sangyo |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

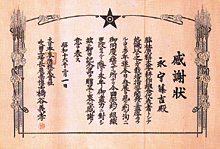

| As a Processional Spent Grain Distributor Tobei was a pioneer, Tokichi, the great successor, and the third generation Masamoto was an innovator, who developed a means of effectively using brewery and spent distilling grains to make feed products. Masamoto founded Meiwa Sangyo in 1960. Meiwa Sangyo continued to grow steadily and extensively promoted the distribution of spent grain feed products, providing immediate solutions to feed issues affecting the cattle farming industry. However, after these issues had virtually been resolved, baseless arguments denying the merit of spent grain feeds arose, severely impacting the business of Meiwa Sangyo and other spent grain distributors. It was in the 1980s, several years after Shotaro, the fourth successor had assumed the presidency. Shotaro was adamant. He assigned Yasuyuki Takada, Senior Executive Manager of the company and a D.V.M. (Doctor of Veterinary Medicine) to conduct research and tests to calm misunderstandings on the part of the general public. With special cooperation by an institute affiliated with the Ministry of Agriculture, Forestry and Fisheries (the most authoritative in Japan), the effectiveness of spent grain feeds as well as their optimum feeding methods were studied. After a series of field tests, finally the truth was revealed: the use of spent grains as animal feed was very effective and efficient, even enhancing farming productivity. In the words of the saying, with adversity comes opportunity. Meiwa Sangyo used this experience to establish its unique distribution system combined with regular lecture and seminar sessions and field guidance for customers to promote spent grain feeds and secure their status as an efficient moist-type product. The next challenging project for Meiwa was the promotion of liquid-type feeds (especially based on the excellent properties of the residual concentrated liquid generated in whisky distilling), which was still a new concept in Japan. Concentrated liquid was used to compensate for the moisture loss in the dry feed manufacturing process and to develop an innovative semi-liquid (wet-form) type product, in which the maximum nutrition level could be maintained. This was just an example of the original Meiwa spirit, even transcending established ideas. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Advancing through a Storm of Liberalization In 1991, the Japanese government liberalized beef imports, greatly affecting the national cattle farming business. Breeders of high-grade Wagyu (Japanese-bred species) had a competitive advantage due to its superior quality; however, those of other species such as Holsteins suffered a huge blow. Their only option for survival was to enhance the meat quality and provide the market with a taste superior to that of imported beef products. One of the key factors to enhance beef quality is "marbling", only produced in animals bred for extended years. However, the longer the breeding period, the more fibrous feed was required, which now brought new issues: the difficulty in sourcing a continuous and stable supply of such feeds and soaring costs incurred by farmers. Despite the enormous demand for fibrous feed, Japan imports most of it, which tends to make it more expensive than concentrated types. Moreover, feeding fibrous feed to cattle requires extra labor, which is an additional cost. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RUMENFIBE, an Innovative Solution Meiwa Sangyo was determined to tackle such issues together with customers, and after many years of laborious R&D, they created "RUMENFIBE", an innovative solution for the welfare of the livestock industry in Japan. It was approved by the Ministry of Agriculture, Forestry and Fisheries as a veterinary medical product in 1992. RUMENFIBE is a mechanical rumen stimulating brush device, designed to substitute the function of fibrous feed such as straw and dried forage, which is essential to promote rumination in the rumen of ruminants. Generally speaking, active rumination requires said feed in bulk, but RUMENFIBE can change this completely. With a single administration, the rumen stimulating effect continues throughout the animal's lifetime, enhancing productivity and management efficiency, as well as slashing costs. With its market launch, RUMENFIBE became a hit product, receiving remarkable responses from cattle breeders nationwide. Hectic follow-up production to refill stock continued. As of 2010, more than 800,000 units had been marketed, and more than 270,000 beef bodies bred with RUMENFIBE have been shipped. For further product enhancement, Meiwa Sangyo continues advanced R&D. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RUMENFIBE is the crystallization of enduring R&D efforts. Since its market launch in 1992, more than 800,000 units have been sold. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The spirit of Meiwa that says "Nurturing our customers' prosperity through our products" has been passed down from one generation to another, now succeeded by its fifth president, Tadashi Nagamori and his employees. Positioning themselves not only as specialized cattle feed suppliers, but also a comprehensive livestock business pioneer for tomorrow, Meiwa Sangyo marks a constant and steady stride ahead, day by day, into continued future growth. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||